Custom Roll Forming Services in Warren, MI

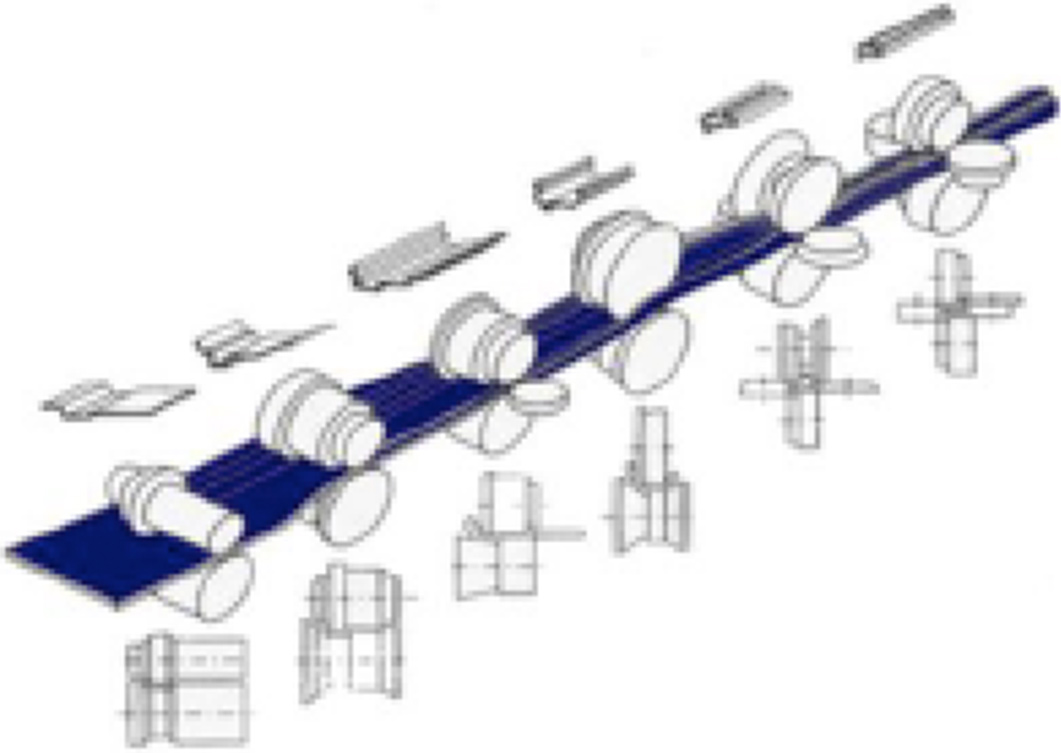

Roll forming is a continuous bending operation, ideal for making components with a consistent profile running the entire length of the part, in which coiled sheet metal is passed through a horizontal series of rolling dies to produce a uniform cross-section shape. The advantages of using the roll forming method are extremely tight cross sections, tolerances, minimal scrap, and dramatically faster production versus press brake operations.

Our Professional Tooling and Equipment are the Key to Transforming Your Designs into Perfectly Formed Steel and Aluminum Components

No matter what project you need custom metal roll formed pieces for, we have the experience, equipment, and tooling to deliver. Our history of produced roll form shapes range from small store fixtures to truck and trailer parts, and everything in between. Industries such as agriculture, construction, wind and solar power, and more rely on our steel and aluminum roll formed shapes across the nation. As you may know, tooling represents a substantial up-front cost in deciding to roll form a part and is often the deciding factor on a limited volume of parts. Over a span of 40 years, we have accumulated tooling for many shapes that we make available to our customers at no additional charge.

MMC employs the most advanced and reliable equipment available to produce high-quality parts at a globally competitive price. Our automated processes allow us to pierce holes, slots, and even extrude fasteners in line- all to add value and save our customers cost on secondary operations. Contact us to discuss your custom roll forming needs and to request a free manufacturing analysis today!

Request a FREE Analysis

We Have Large Scale Capability with Small Company Service

What differentiates MMC Products from other roll forming companies is our flexibility and outstanding customer service. The most critical part of a successful roll forming operation is the people. Our operators, tool and die maintenance team, and set up personnel have decades of experience to produce your part and hold the tightest possible tolerances. This often becomes the deciding factor in our customers' decision to work with us. We offer an extensive list of profiles with no tooling cost to you and amortization options to make doing business with us easier. We simply do things to benefit our customer that other large roll formers can't and won't do. Give us a call today to discuss your project and hear more about the MMC difference!

Call MMC Products TodayWhy Roll Form with MMC:

Roll forming offers inherent economic advantages over other metal forming methods by integrating in-line processes and eliminating the need for many secondary operations. This combined efficiency adds up to reduced cost and time during the manufacturing process. Through the use of in-house tooling as a starting point we are often able to modify, reduce or eliminate the need for a full new set of tooling. If new tooling is required for a custom shape, we have the capability to manufacture in house.

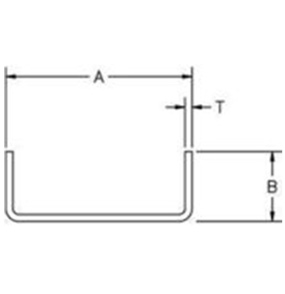

U Channel

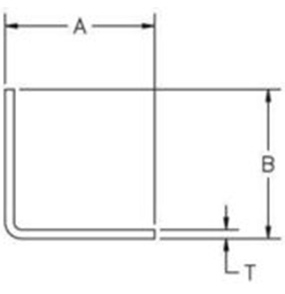

Angle or V Channel

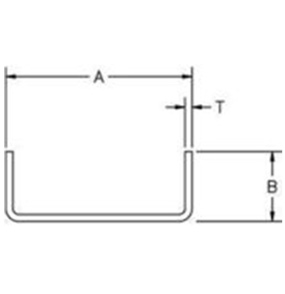

C Channel

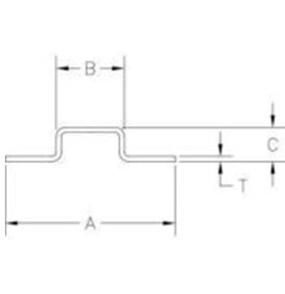

Hat Channel

Capabilities

- 14 Roll Mills

- 1.5" to 3.0" Roll Shaft Diameter

- 8 to 21 Passes

- Constant Sweep

- Pre-Pierce

- Cutoff and Notch

- Offline Fabrication and Assembly

- Long Length & Critical Finish Specialists